Don't see the size you need?

Can't find the walk in cooler&freezer size you need? Coldkin has got you covered! We can create a custom cooler or freezer for you, no matter the size, by utilizing modern refrigeration system and insulated panels.

Contact us today to discuss your needs.

PU Polyurethane PUR PIR PUF Insulated Foam

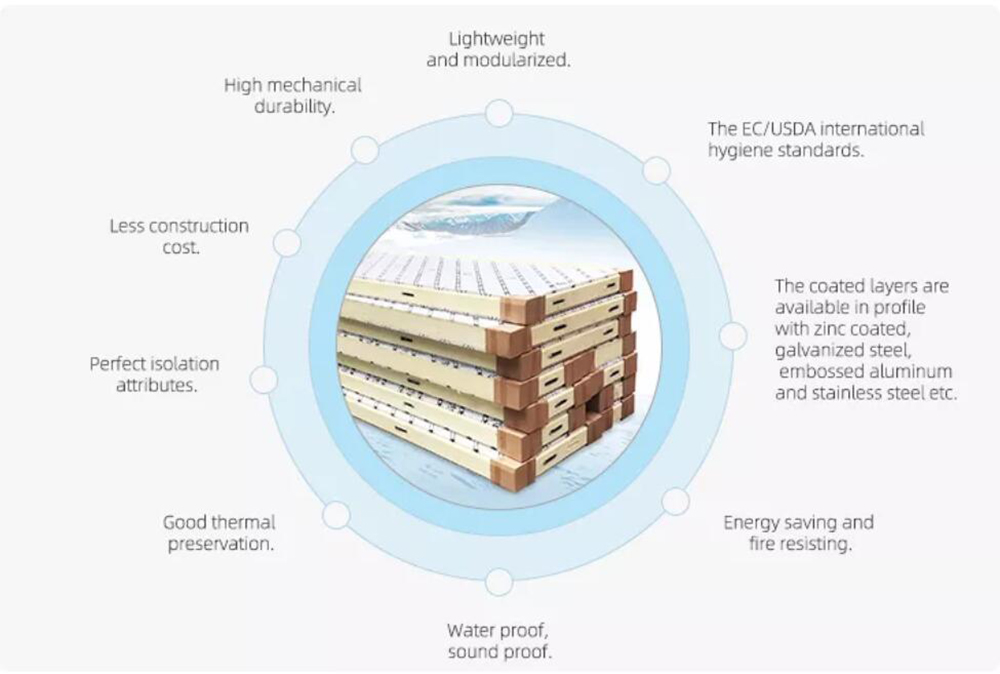

PU panel is also called PU sandwich panel, PUR Panel or PUF Panel in which polyurethane foam is been sandwiched between the two outer covers. The CFC-free insulated PU panel is commonly used as the cold storage panels due to its advantageous mechanical, chemical, biological and moisture properties, it is excellent to prevent thermal conductivity, restrain growth of fungi, keep out moisture ingress. We are engaged in manufacturing reliable PU sandwich panels in variegated specifications.

Coldkin PU panels are available in customized sizes and structure for storage temperature ranges from -36°C to 10°C. The outer two layers are available in profile with zinc coated, galvanized steel, embossed aluminum and stainless steel etc., that can meet the international hygiene standards.

Features of PU Panel

- Lightweight and modularized.

- High mechanical durability.

- Less construction cost.

- Perfect isolation attributes.

- Good thermal preservation.

- Water proof, sound proof.

- Energy saving and fire resisting.

- Competitive in price.

- The coated layers are available in profile with zinc coated, galvanized steel, embossed aluminum and stainless steel etc.

- The EC/USDA international hygiene standards.

|

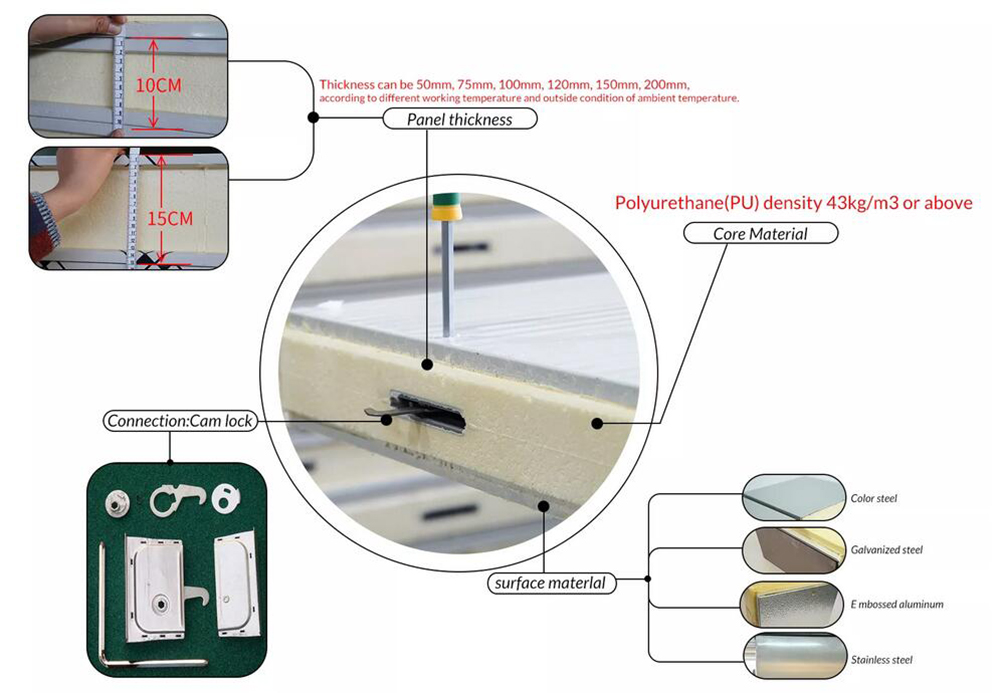

Panel thickness

|

Thickness can be 50mm, 75mm, 100mm, 120mm, 150mm, 200mm, according to different working temperature and outside condition of ambient temperature.

|

|

Core Material

|

Polyurethane(PU) density 43-45kg/m³ or above

|

|

Panel length

|

12m or customized

|

|

Surface Material

|

Color steel, galvanized steel, embossed aluminum, stainless steel

|

|

Thickness

|

Application Temperature

|

|

50MM

|

Above 15°

|

|

75MM

|

Above 5~15°

|

|

100MM

|

Above -5~5°

|

|

120MM

|

Above -18~-5°

|

|

150MM

|

Above -40~-18°

|

1. Before the installation, make sure that the locking devices are at the stop position. To do so, turn the locking devices counter-clockwise, using a wrench with force, until it stops.

2. Push panels together and turn wrench 1/4 turn clockwise. This will engage the male locking device ‘arm’ over female locking device ‘pin’.

3. Keep turning the wrench for another turn until the wrench stops. If there are any problems during the operation of cam locks, turn the wrench counter-clockwise with force until it stops moving any further. This will put the locking device at its original position and you can try to assemble the panel again by moving the wrench in a clockwise direction.